Round tables

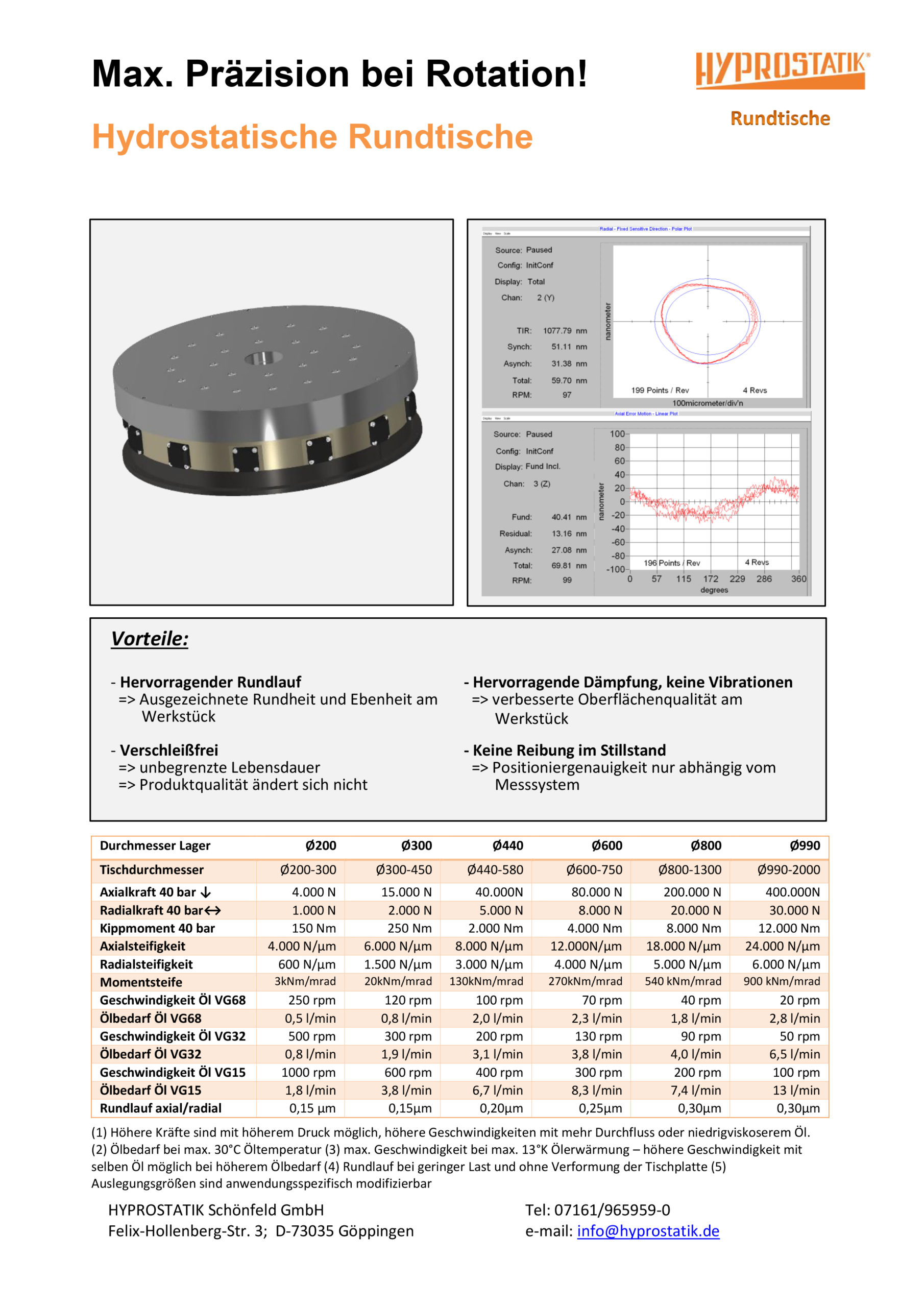

Round tables of the highest quality – now up to 2.5 m in diameter

The requirements for round tables are constantly increasing and we have expanded our range accordingly. We now offer round tables with a diameter of up to 2.5 meters, manufactured directly in-house.

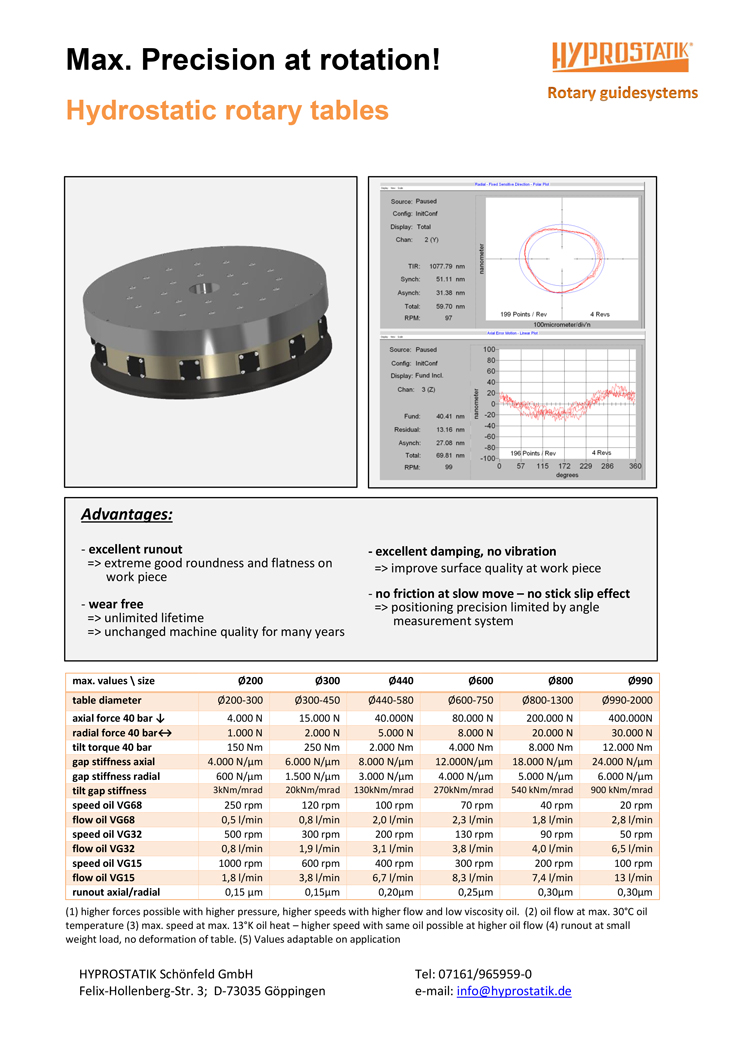

Our rotary tables are characterized by exceptional roundness and flatness that are hard to beat. The excellent damping and freedom from vibration contribute significantly to improving the surface quality of your workpieces. Thanks to frictionless positioning at standstill, the positioning accuracy depends solely on the measuring system used.

For detailed information, please download our data sheet or contact us using the contact form. We look forward to your inquiry!

Rotary tables over 2.5 meters – Tailor-made solutions from our partners

For rotary tables with a diameter of over 2.5 meters, we offer you tailor-made solutions in cooperation with our qualified partners. Hyprostatik calculates the specific requirements and provides the necessary components, such as our swivel pockets, to meet your individual needs. For example, we were able to realize customer requirements for rotary tables with a diameter of 15m.

Contact us for more information and let us work together to find the perfect solution for your requirements

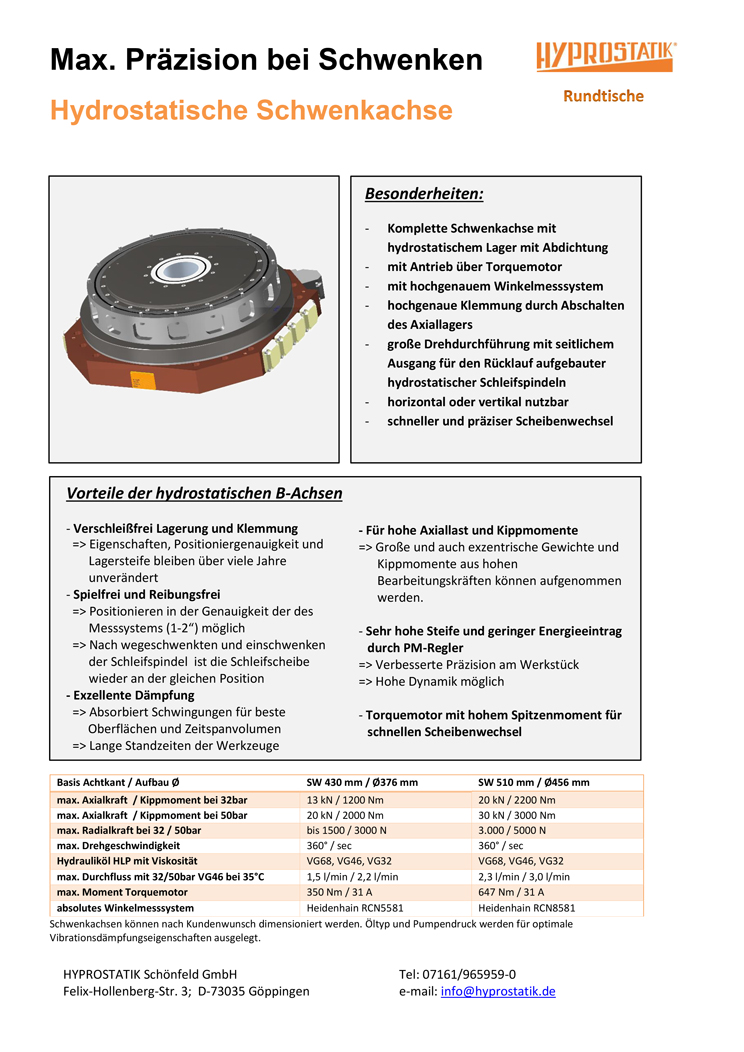

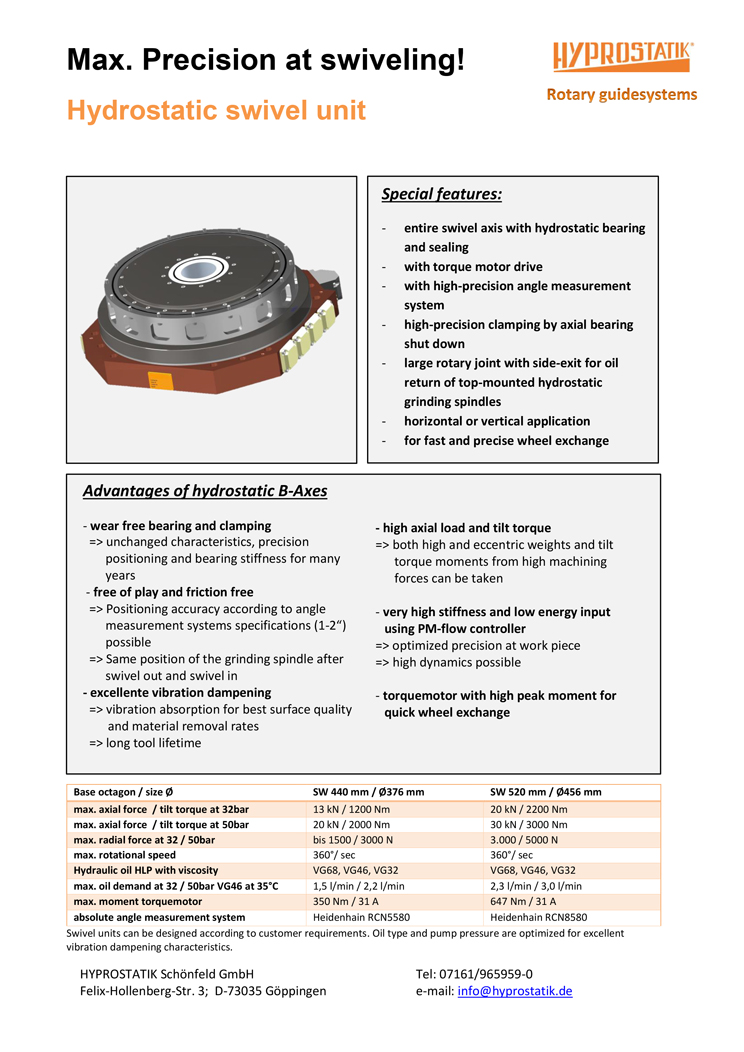

Innovative swivel axes (B-axes) – special design of our hydrostatic rotary table

Our innovative swivel axles, also known as B-axles, are a special design of our hydrostatic rotary table. This complete swivel axis is equipped with a hydrostatic bearing and air-sealed bearings. It is driven by a torque motor, which is specially selected according to the respective requirements. The B-axis also has a high-precision angle measuring system and clamping by switching off the axial bearing, which achieves a clamping force of up to 45 kN.

The large feed-through with side exit enables the return of a mounted hydrostatic grinding spindle, transforming the B-axis into a high-precision grinding machine. The B-axis can be used both horizontally and vertically, whereby the grinding wheel can be changed quickly and precisely.

Advantages of our B-axles:

- Wear-free bearing and clamping

- Properties, positioning accuracy and bearing rigidity are retained for years.

- Backlash-free and frictionless

- Positioning with an accuracy of 1-2 µm possible.

- The grinding wheel remains in the same position after the grinding spindle has been swiveled away and swiveled back in.

- Excellent cushioning

- Absorbs vibrations for the best surfaces and secondary chip volumes.

- Long tool life.

- High axial load and tilting moment capacity

- Large and also eccentric weights as well as tilting moments due to high machining forces can be absorbed.

- Very high stiffness with low energy input due to PM controller

- Improved precision on the workpiece.

- High dynamics possible.

- Torque motor with high peak torque

- Fast and precise loop changes are guaranteed.

For detailed information and inquiries, please do not hesitate to contact us. Visit our website or contact us directly using the contact form.

Flyer download area

All about rotary tables and B-axis