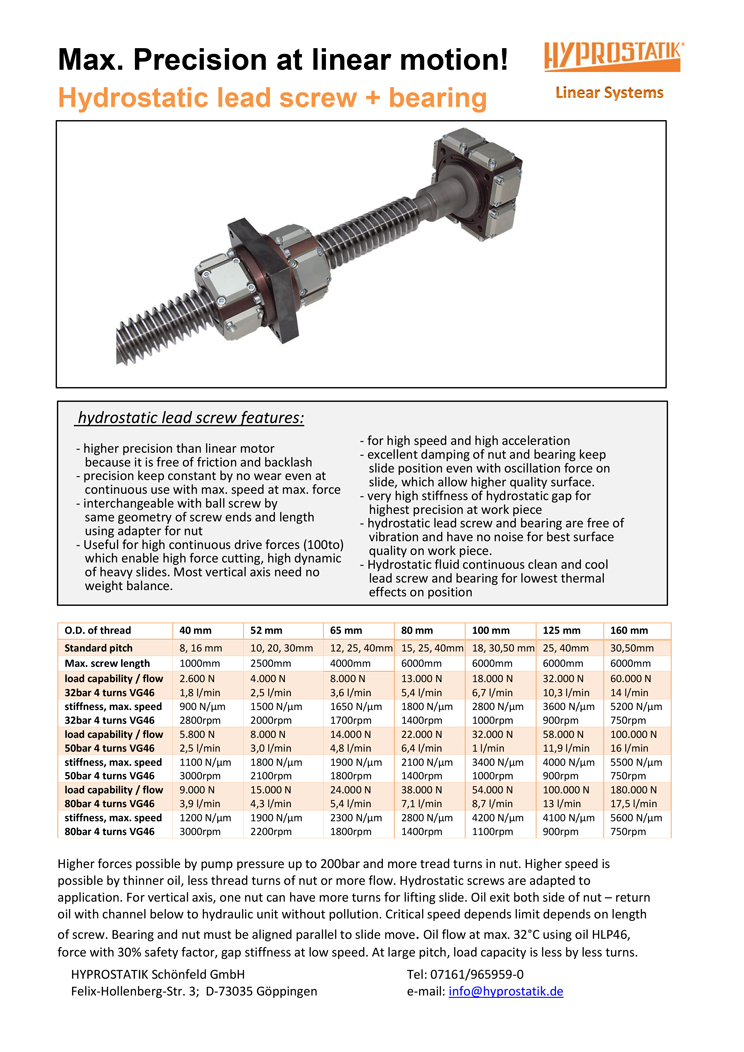

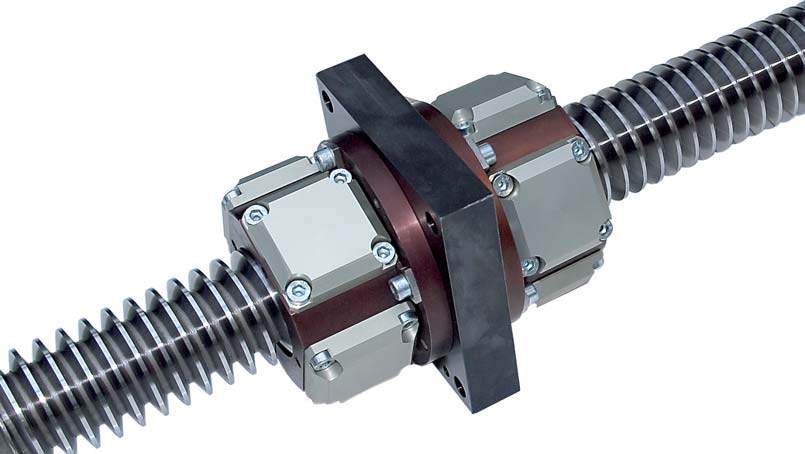

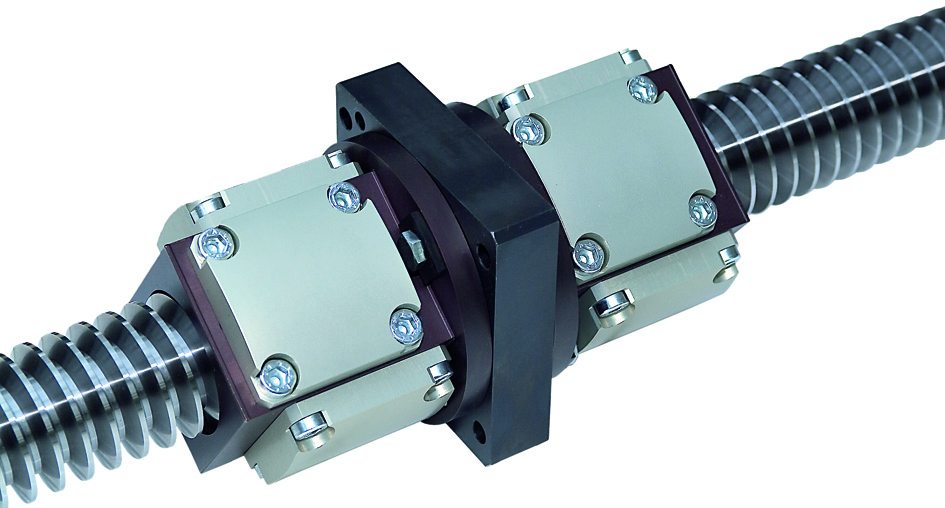

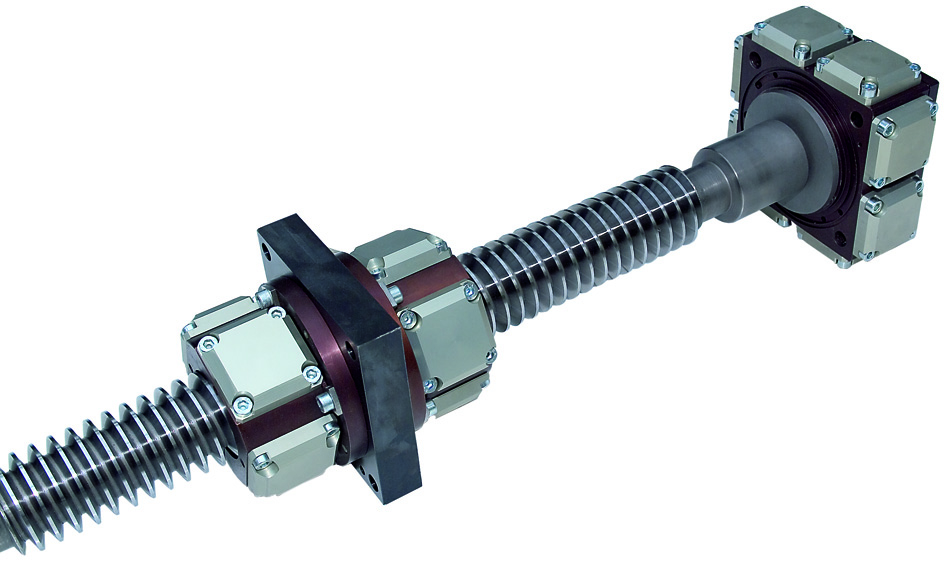

Worldwide unique hydrostatic screw drives – all advantages at 1 glance

15 Advantages of lead screws compared to ball screws & roller bearings:

- Wear-free, as there is no contact during operation

- No loss of accuracy, even during long periods of operation under full load at maximum power.

- Speed

- Friction-free at low speeds

- No reversal of the frictional force when changing the direction of rotation

- Transmits the slightest rotary movements

- No stick-slip effect even at low speeds

- No fluctuations in the frictional torque due to ball circulation

- Higher axial stiffness than ball screws

- Much better damping: therefore better workpiece surface and tool life

- No vibrations due to the ball circulation

- Also suitable for high speeds and acceleration

- low-cost alternative to the linear motor with higher accuracy, much lower

- Heating

- Much lower power loss and therefore no problems with chips on the permanent magnet

- Many times lower cooling capacity than linear motors

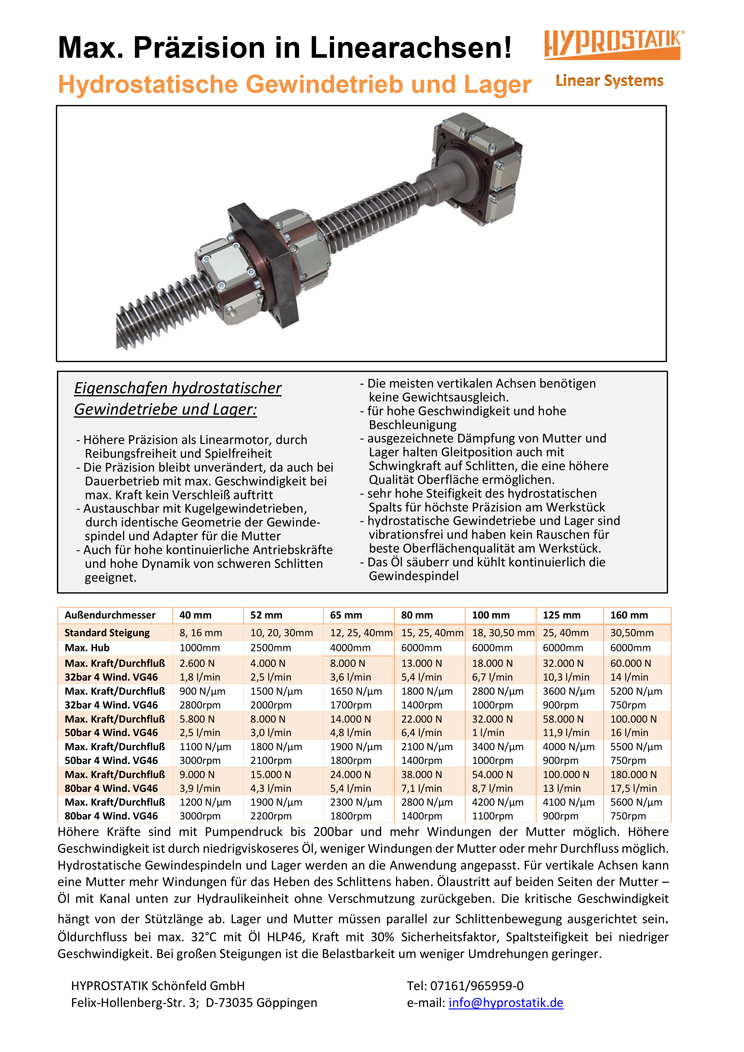

8 technical features of our screw drives:

- Absorption of axial and radial forces and torques – Suitable for one-sided mounting of the threaded spindle

- High-precision bearing of the screw drive

- Double cones suspended between hydrostatic pockets for mounting in an “O arrangement”

- Integrated volume control by pocket pressure only, only one hydraulic connection,

- No additional electronic control required

- All supply and discharge lines in the flange surface

- Optional: Sealing to one side with sealing air/gap seal or sliding seal

- Spindle ends are designed according to customer requirements

Adjustment of the hydrostatic nut:

- Axial load in both directions

- max. Speed

- Desired stiffness

Do you have any questions about screw drives?

We advise you!

07161 965959-0

info@hyprostatil.de

HYPROSTATIK Schönfeld GmbH

Flyer download area

All about screw drives