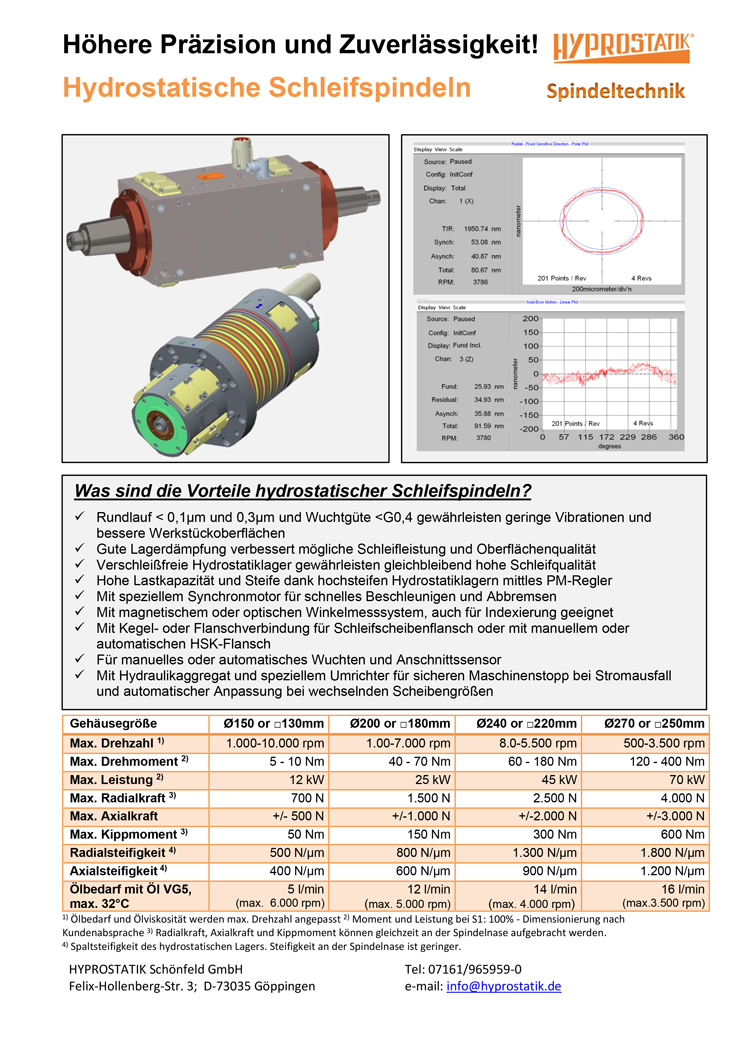

Spindellagerungen von HYPROSTATIK Schönfeld – Technologie für höchste Präzision

Die von der HYPROSTATIK Schönfeld GmbH entwickelte hydrostatische Technologie bietet zahlreiche Vorteile für Werkzeugmaschinen wie Dreh-, Fräs- und Schleifmaschinen sowie komplette Bearbeitungssysteme. Dank unserer mehr als 30-jährigen Erfahrung erhalten Kunden weltweit maßgeschneiderte Lösungen für höchste Präzision und Investitionssicherheit. Das liegt nicht nur an der herausragenden Fertigungsqualität unserer Spindellagerungen, sondern auch an dem Einsatz unseres innovativen Progressiv-Mengen-Reglers und den umfangreichen Berechnungsprogrammen, mit denen wir arbeiten.

Durch die hydrostatischen Komponenten werden Berührungen zwischen bewegten und unbewegten Teilen verhindert – das sorgt für verschleißfreie Lagerungen und konstante Qualität über viele Jahre hinweg.

Unsere Produktlösungen im Überblick

-

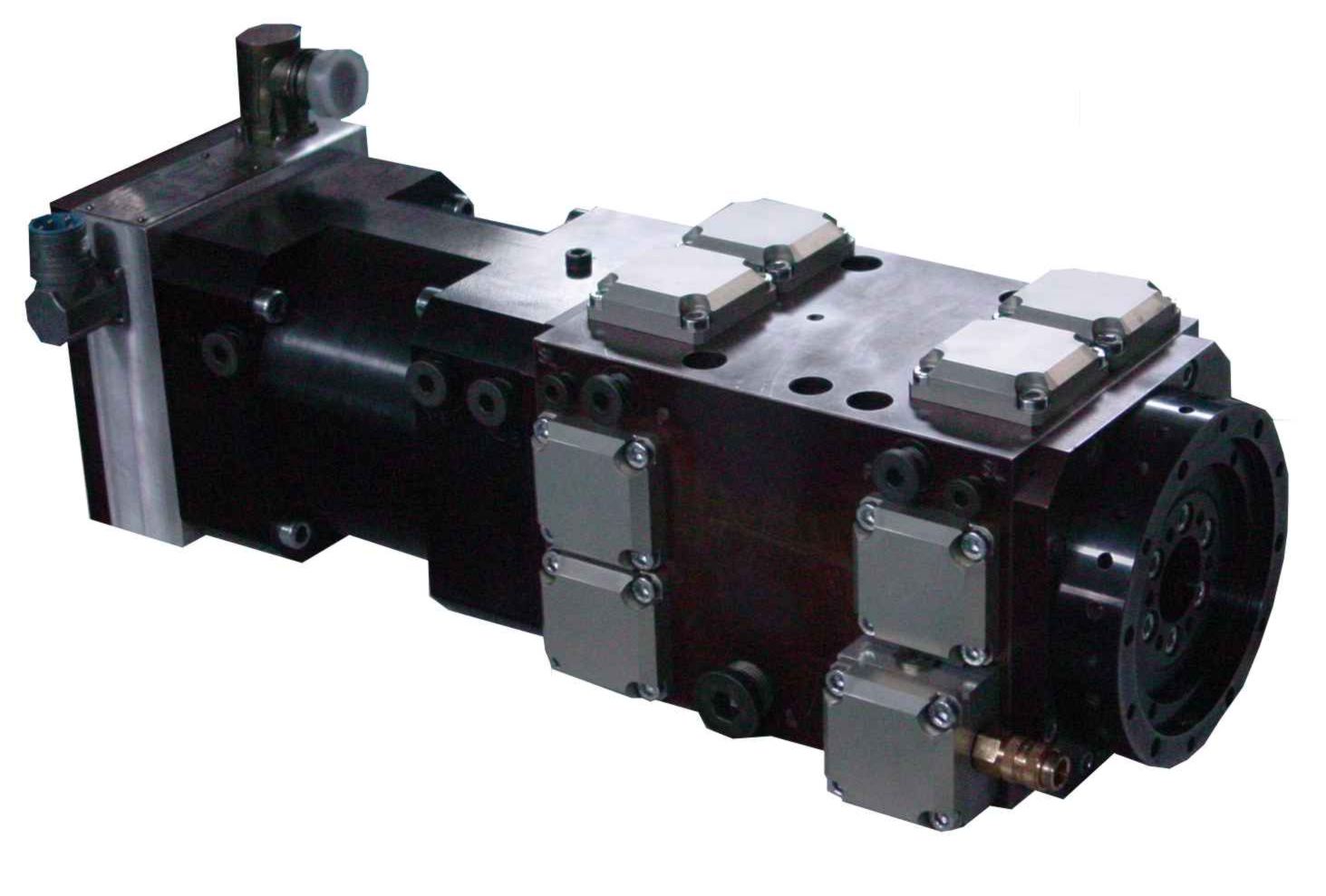

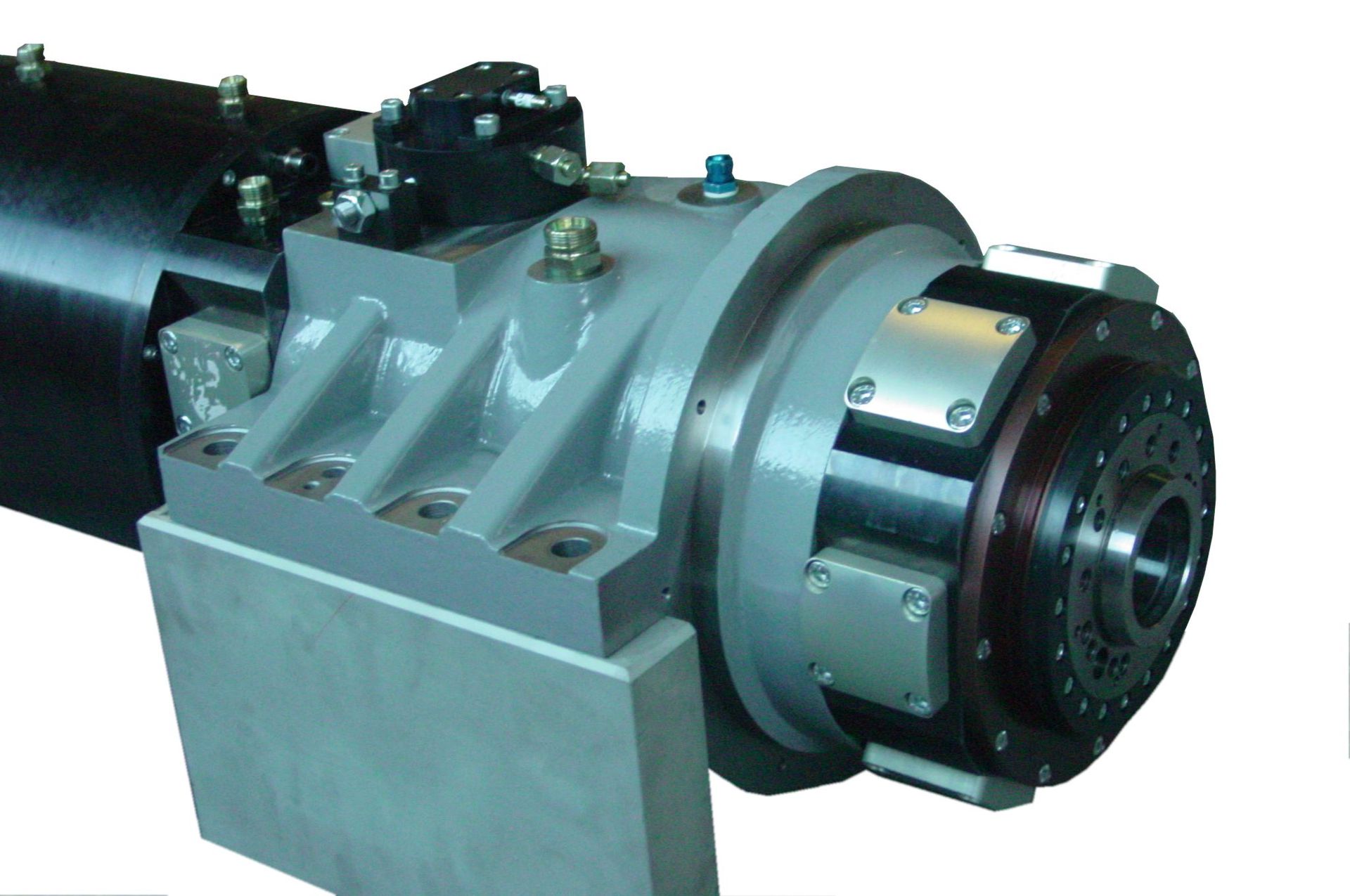

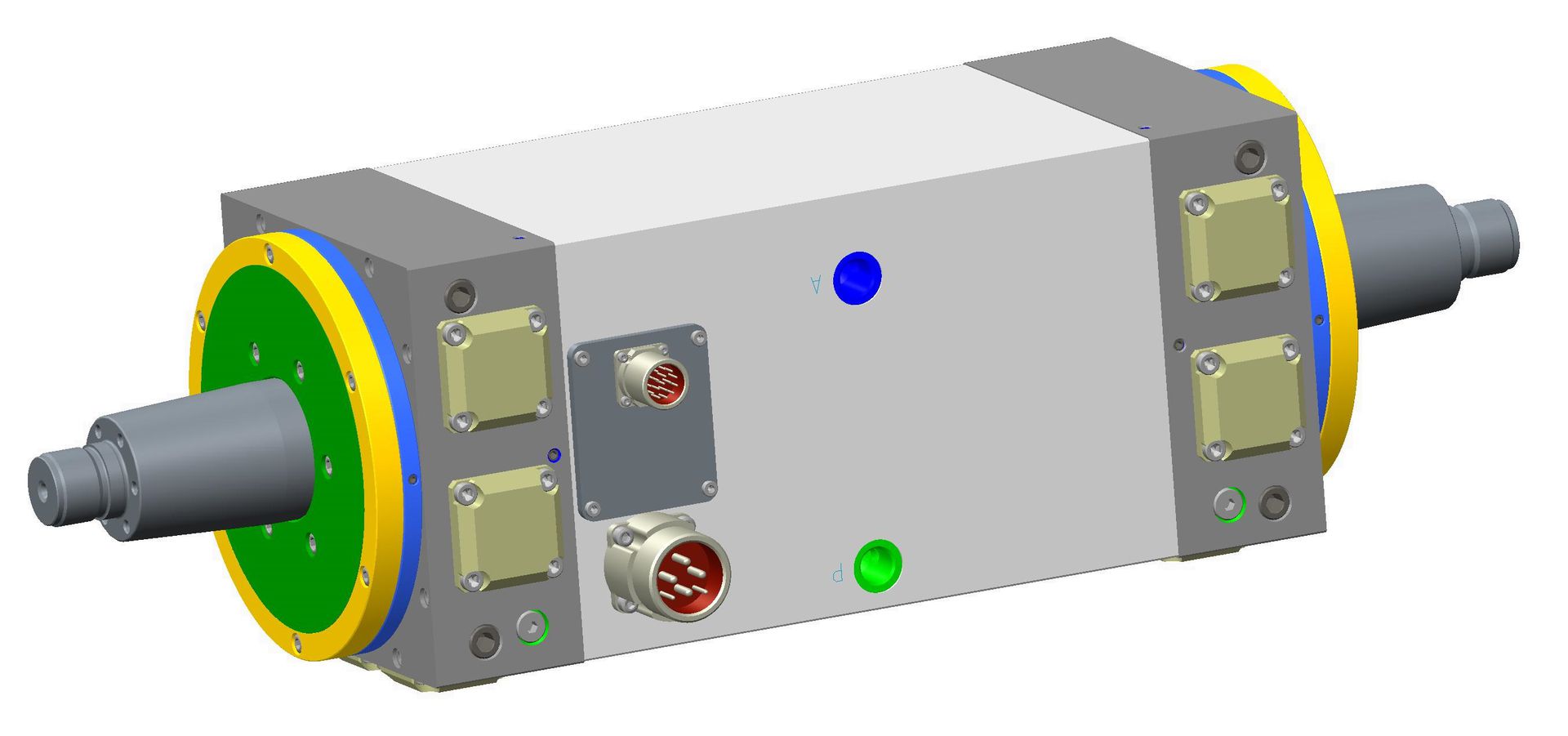

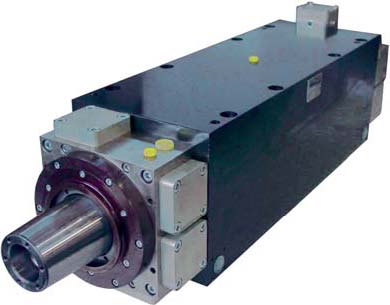

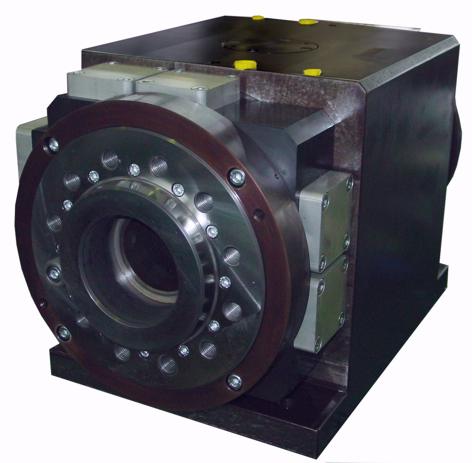

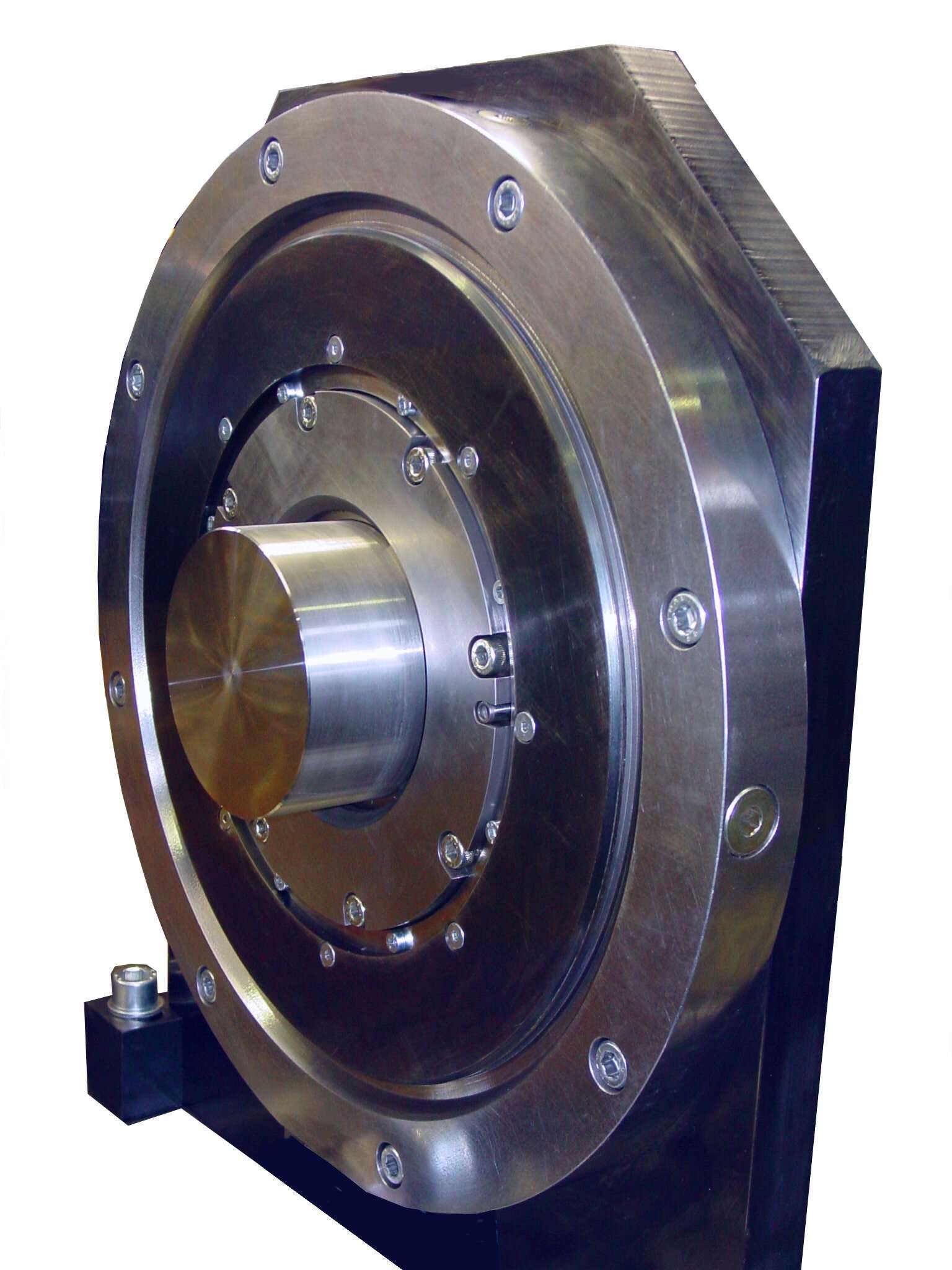

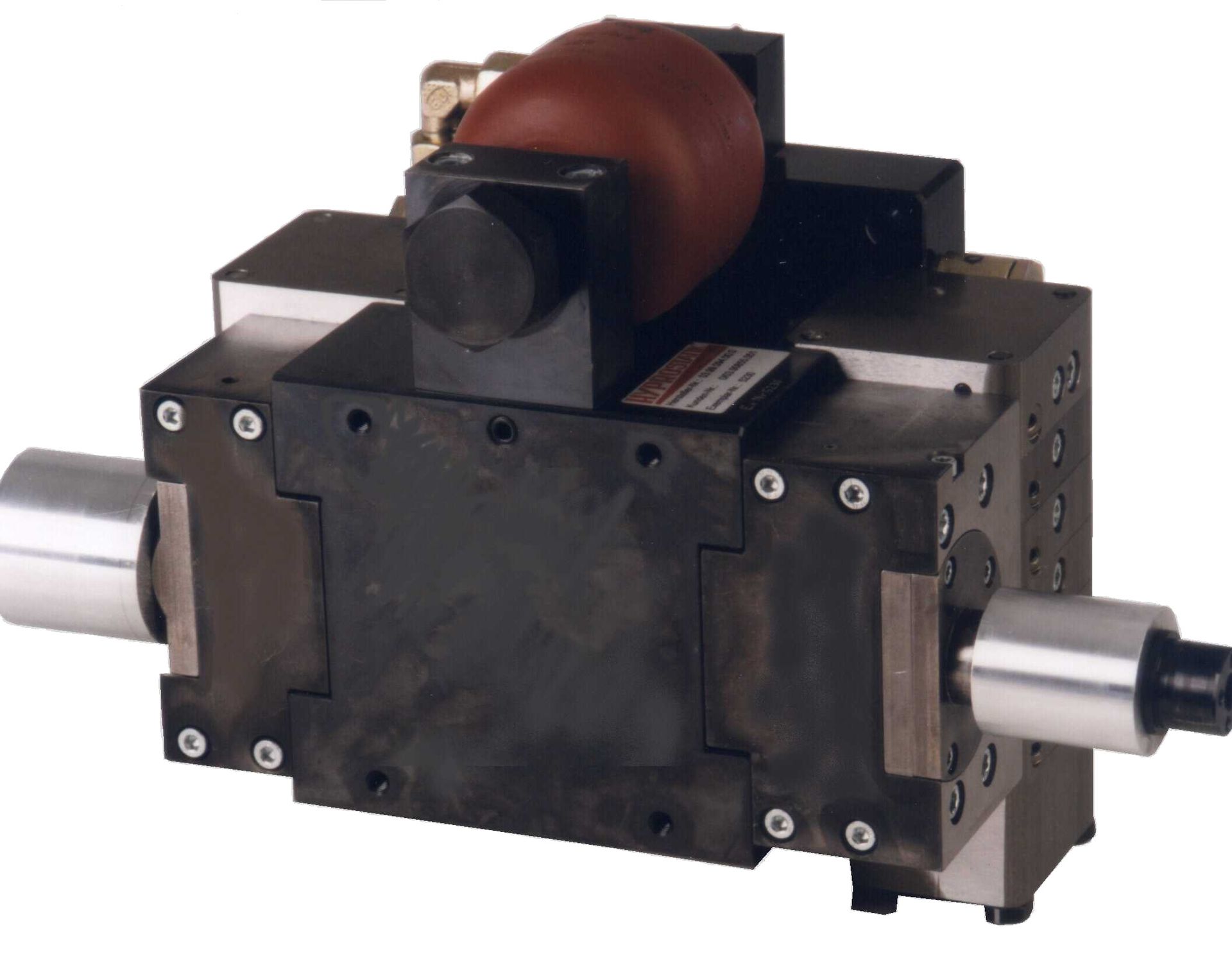

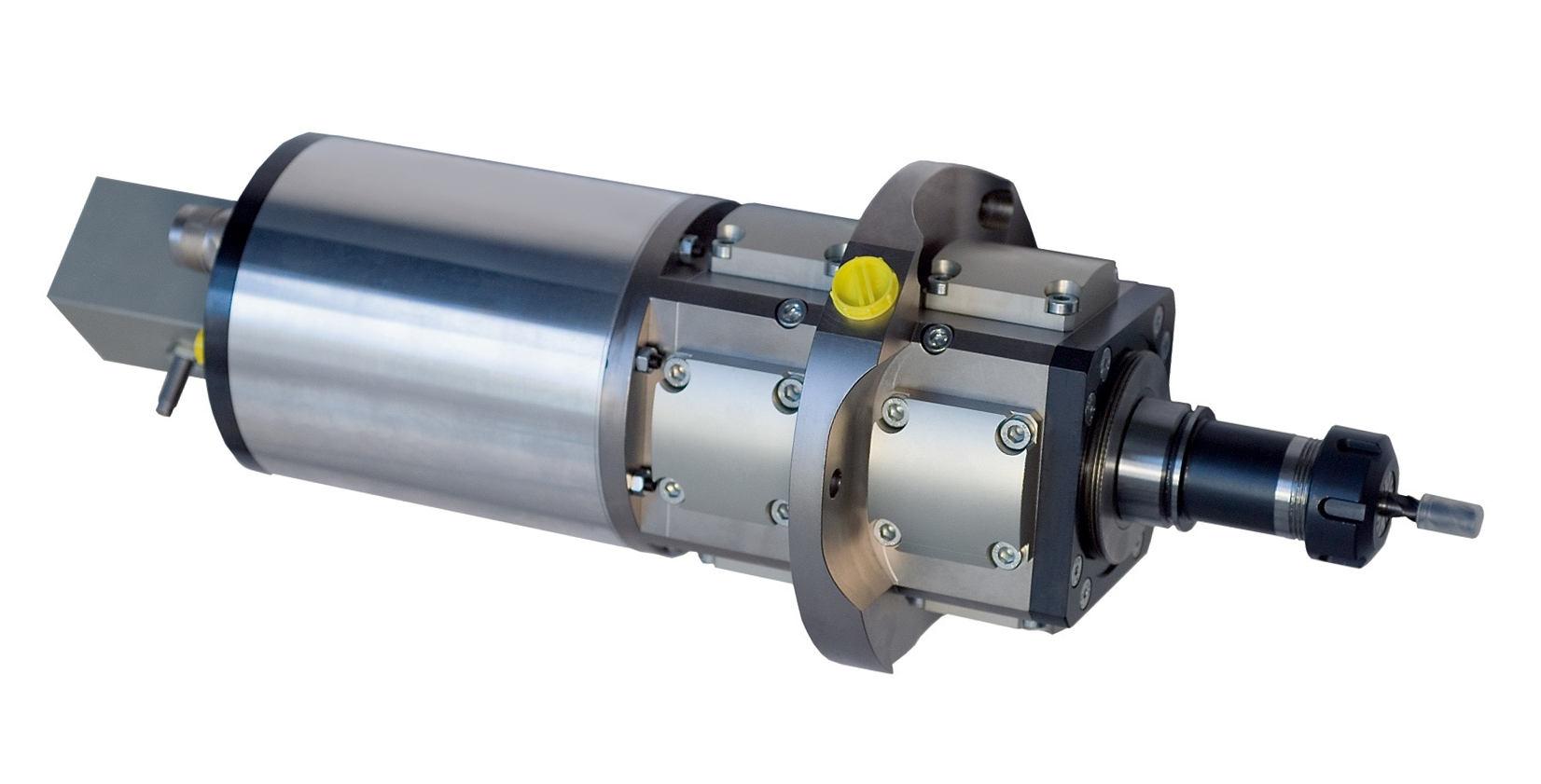

Unser System HYPROSTATIK® umfasst ein breites Sortiment an Spindellagerungen für unterschiedlichste Anwendungen.

Die Spindellagerungen unseres Systems HYPROSTATIK® bieten zahlreiche Vorteile. Sie arbeiten verschleißfrei und weisen deshalb Eigenschaften auf, die unabhängig von der Gebrauchsdauer sind. Hinzu kommen eine sehr hohe Rund- und Planlaufqualität, eine exzellente statische und dynamische Radial- und Axialschleife sowie Dämpfung. Mit unserem patentiertem Progressiv-Mengen-Regler (PM-Regler) erzielen wir eine äußerst geringe Reib- und Pumpenleistung und mit weitreichenden Berechnungsprogrammen eine bestmögliche Auslegung. Die Ölkühlung und Wärmeisolation zwischen der Spindellagerung und dem Motor sorgt für einen minimalen Temperaturgang von wenigen Grad Celsius. Schließlich sei noch die herausragende Wuchtgüte erwähnt.

Den Kern unserer Produktion bildet ein Sortiment von Serienspindeln. Sofern technisch machbar, bieten wir unseren Kunden bei größeren Stückzahlen und wiederkehrenden Aufträgen aber auch Sonderausführungen an. Sprechen Sie mit uns, wenn Sie spezifische Spindellagerungen für Ihre Branche und Ihre Anforderungen benötigen. Bei unseren Serienspindeln haben Sie die Wahl zwischen:

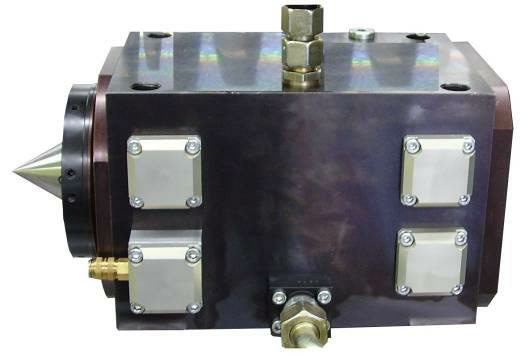

- Motorspindellagerungen: Hydrostatik für Schleifmaschinen, Werkstückspindeln oder Drehmaschinen

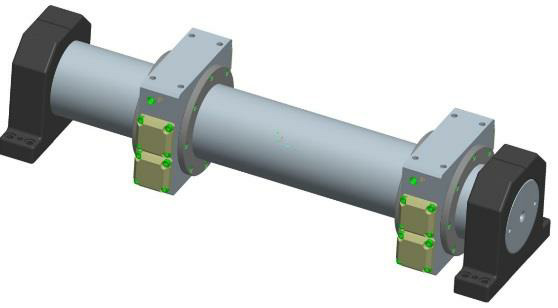

- Extern angetriebene Spindellagerungen: Riemenspindeln, Direktantriebe oder Hauptspindeln

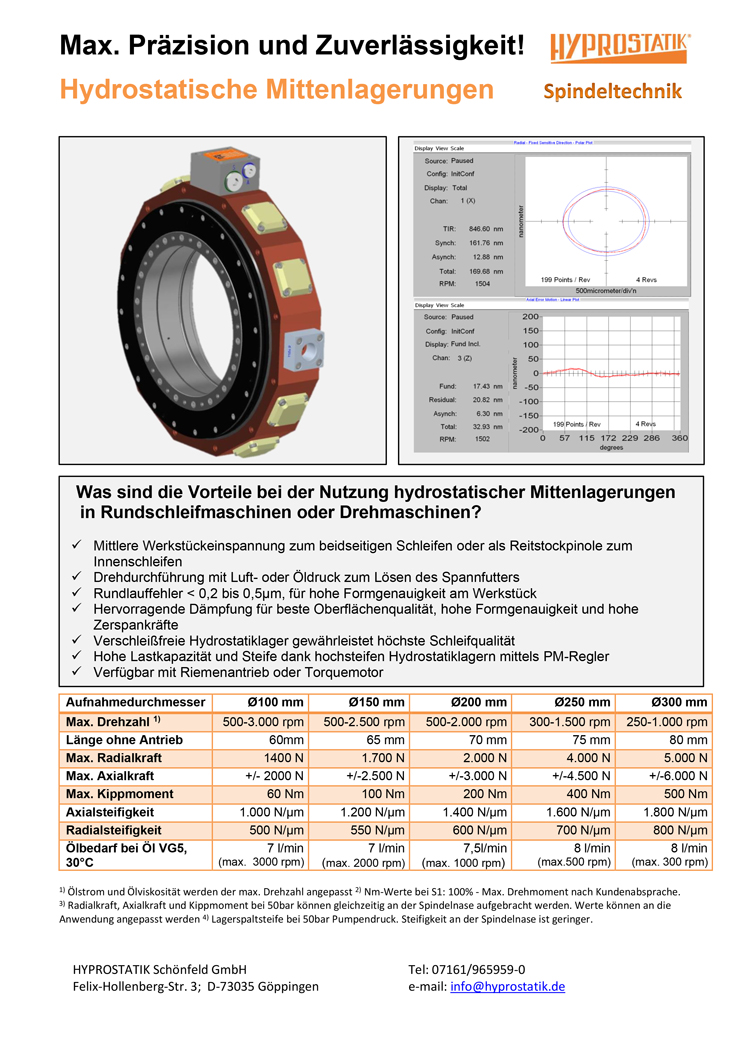

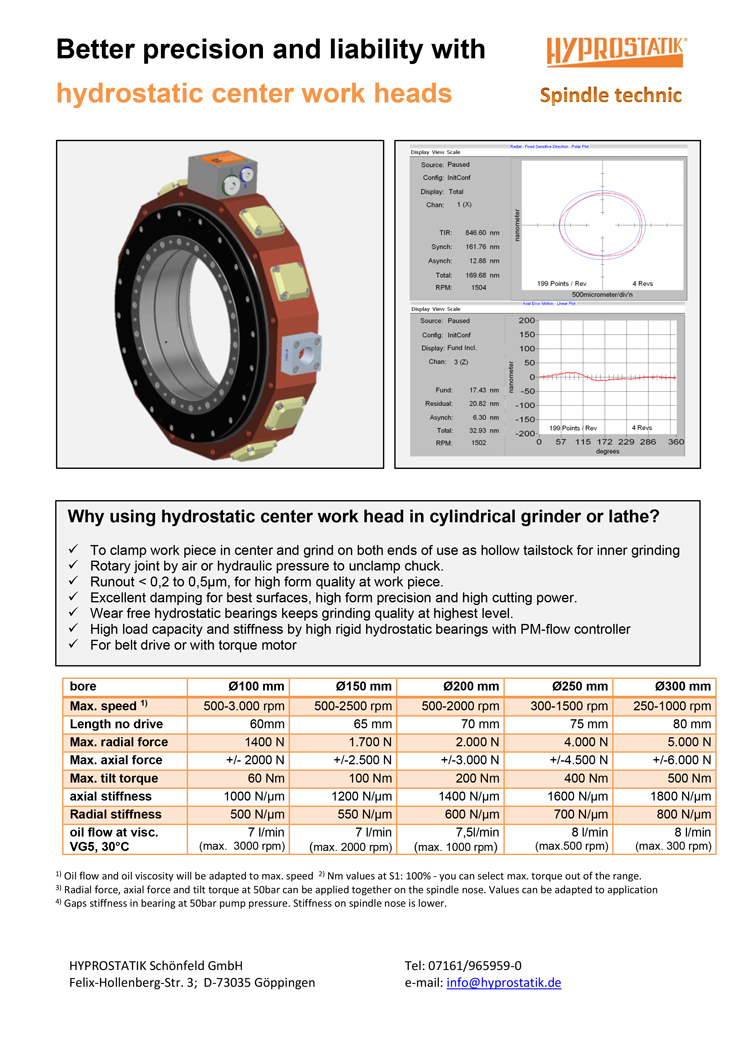

- Mittenlagerungen: Für beidseitiges Schleifen oder Drehmaschinen

- Sonderlagerungen: Hochfrequenzspindeln, Nockenschleifspindeln, Reitstöcke oder Schwenktaschen

Vorteile unseres PM-Reglers an hydrostatischen Spindellagerungen Systemen HYPROSTATIK®

Unsere hydrostatischen Spindellagerungen bieten Ihnen zahlreiche Vorteile, die sich direkt auf die Qualität und Produktivität Ihrer Maschinen auswirken:

1. Verschleißfreiheit & Langlebigkeit

Da zwischen den bewegten und unbewegten Teilen keine Berührung stattfindet, entsteht kein Verschleiß. Das sorgt für eine konstant hohe Leistung und eine lange Lebensdauer – selbst bei jahrelangem Dauereinsatz.

2. Höchste Präzision

Die Lagerungen bieten eine sehr hohe Rund- und Planlaufqualität, sodass Formfehler minimiert werden. Das führt zu einer besseren Oberflächenqualität Ihrer Werkstücke.

3. Thermische Stabilität

Durch die integrierte Ölkühlung und Wärmeisolation bleibt die Temperatur der Lagerung selbst bei hohen Drehzahlen konstant. So wird eine gleichbleibende Präzision gewährleistet – unabhängig von der Betriebsdauer.

4. Maximale Belastbarkeit

Dank der PM-Regler-Technologie können unsere Spindellagerungen auch bei höchsten Drehzahlen voll belastet werden, ohne an Steifigkeit oder Funktionssicherheit einzubüßen.

5. Geringe Betriebskosten

Die verschleißfreie Technologie reduziert den Wartungsaufwand auf ein Minimum. Das führt zu weniger Stillstandzeiten und geringeren Wartungskosten.

6. Energieeffizienz

Durch den PM-Regler wird der Ölstrom, der Pumpendruck und die Ölerwärmung deutlich gesenkt – im Vergleich zu herkömmlichen Kapillarreglern.

Hydrostatische Spindellagerungen von HYPROSTATIK® – verschleißfrei, hochpräzise & langlebig. Jetzt individuelle Beratung anfordern!

Wollen auch Sie von den Vorteilen unserer hydrostatischen Spindellagerungen profitieren!

Dann nehmen Sie jetzt Kontakt mit uns auf. Wir beraten Sie gerne ausführlich zu allen Details unserer Produkte, damit Sie die optimale Lösung für Ihre spezifischen Anforderungen erhalten.

Let Get personal advice!

“Our spindle bearings are equipped with pioneering technology from HYPROSTATIK. This offers you clear competitive advantages! Minimal friction, no wear, no losses. With a significant gain in precision and service life.”

Your hyprostatics expert team

07161 965959-0

info@hyprostatil.de

HYPROSTATIK Schönfeld GmbH

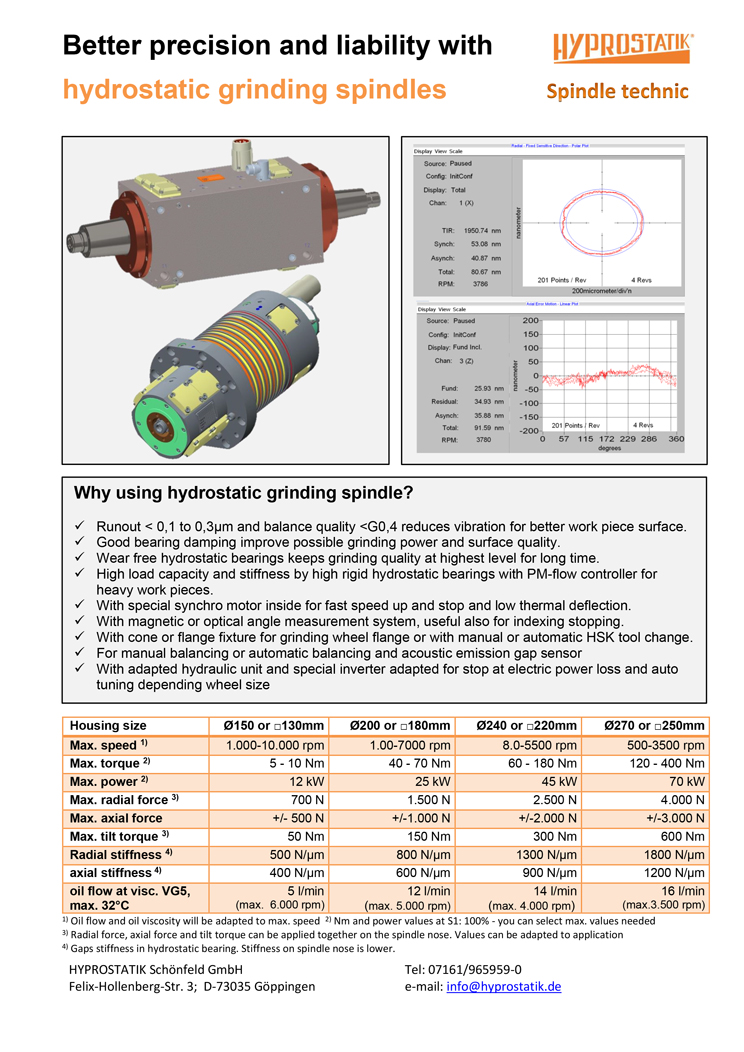

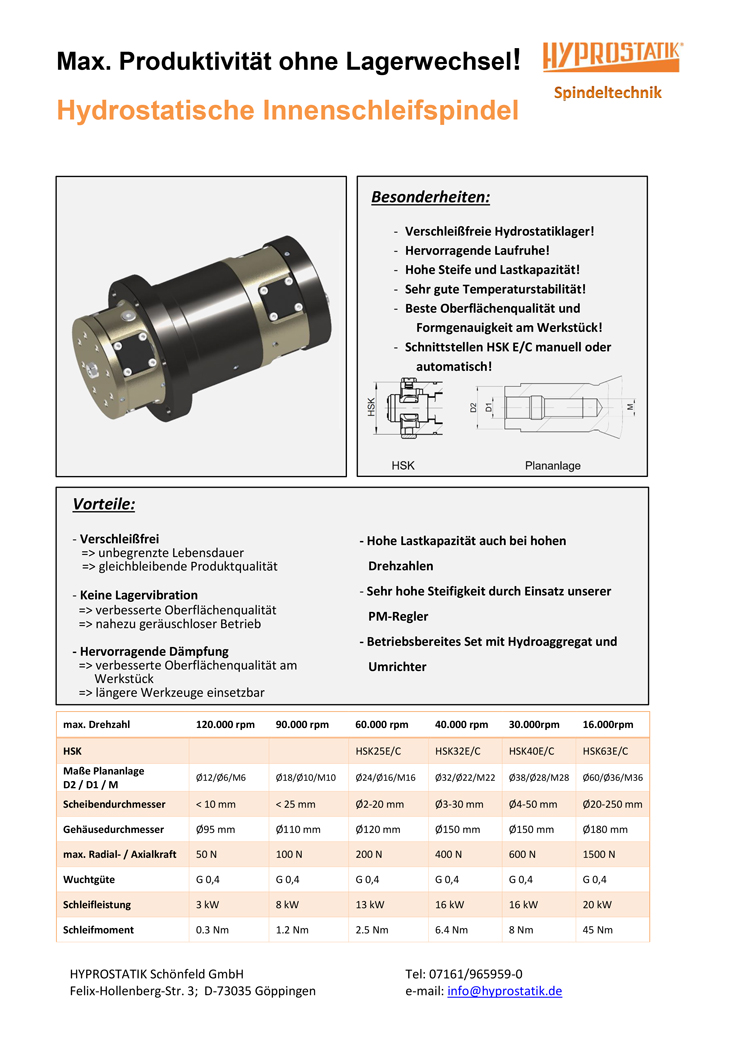

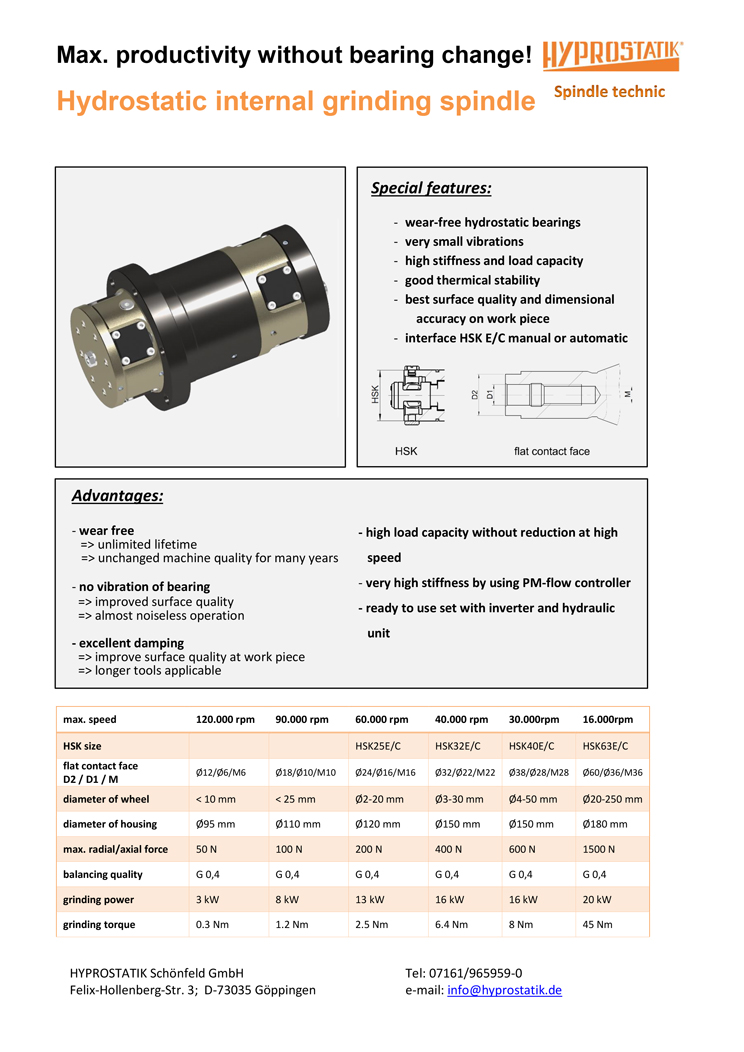

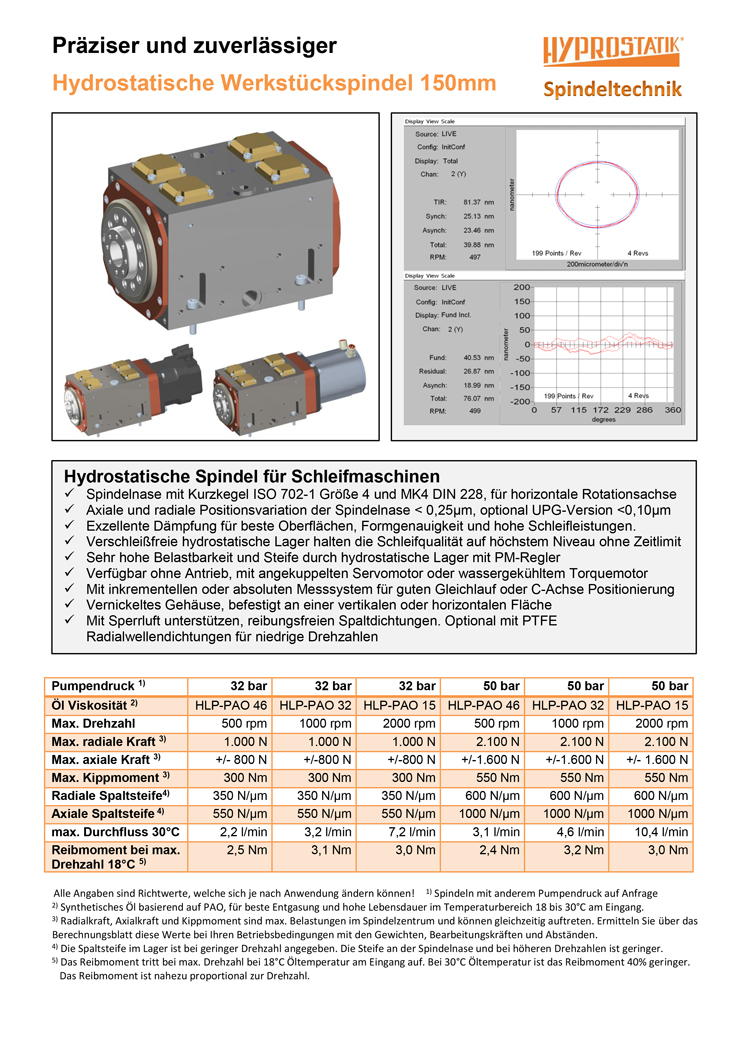

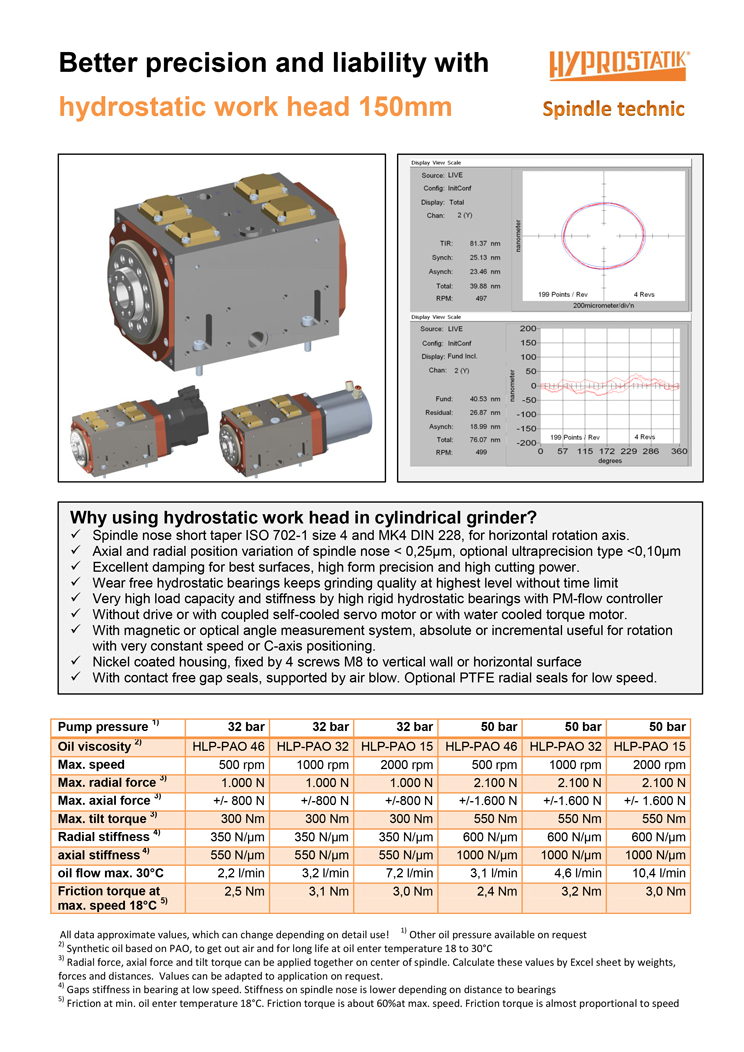

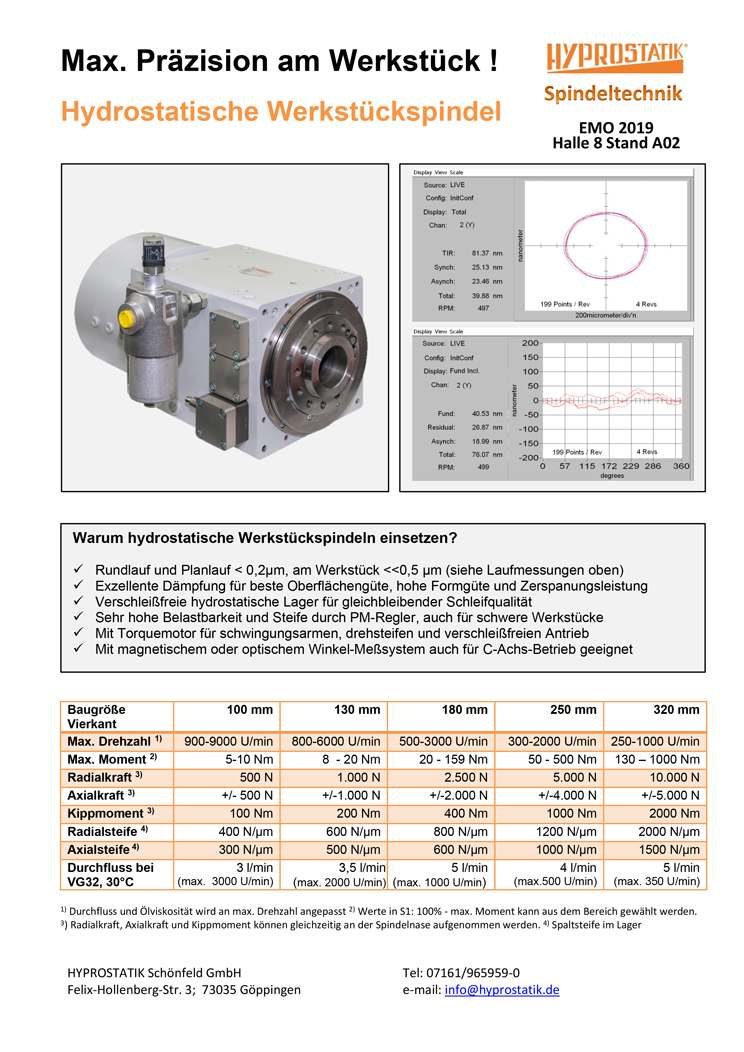

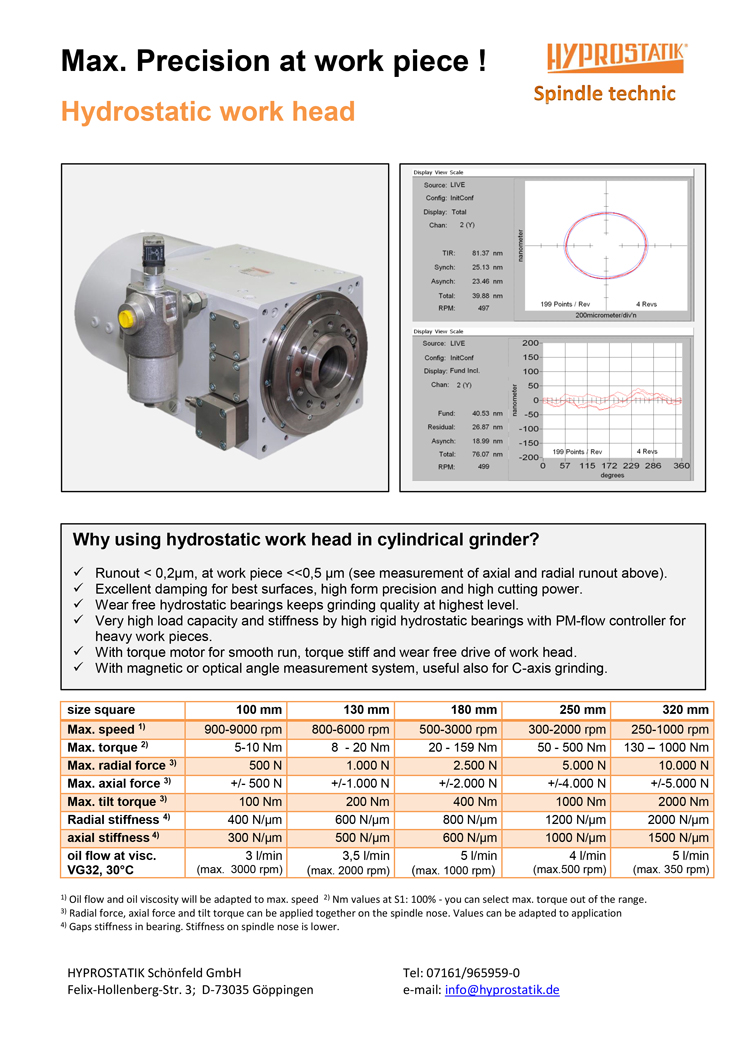

MOTOR SPINDLE BEARINGS

Our aim is to further expand sales of the series spindles listed below.

For higher quantities and/or repeat orders, however, we also offer special designs to the extent possible.

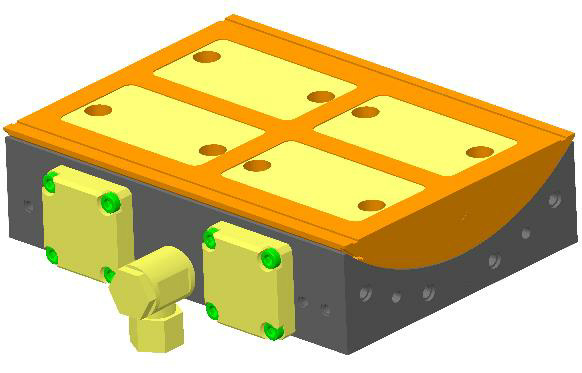

EXTERNALLY DRIVEN SPINDLE BEARINGS

CENTER BEARINGS

SPECIAL BEARINGS

Flyer download area

Everything about spindles and center bearings